Smelter Ovens in San Emigdio Canyon

(29th November 2012)

I'm wondering if these old smelters are in any way connected to the early Spanish (or Mexican) mining activities taking place during the mission era. There is evidence for two early mines in this area, one a silver mine and the other an antimony mine. They started the legend of the "Lost Padre Mine" popularized in newspapers such as the Ventura Signal starting in 1871.

The San Emigdio Canyon was first prospected by the Spanish for minerals in August 1790. There was a later expedition in August 1806 when San Emigdio Canyon was named (before this it was known as the Canyon of the Dead). We know this early silver mine was operating during the widespread Indian revolt of 1824 when the mine was temporarily closed and concealed. Evidence suggests this mine was in operation in the late 1810s and/or early 1820s. Mexico was in control of California by this time but had not yet expelled the Spanish-born priests or confiscated all the Spanish missions in California.

In October 1832, the famed trapper, Ewing Young, and three other men discovered old smelting ovens in lower San Emigdio Canyon near the pre-history, Indian village of Tashlipun. The smelters were assumed to be of Spanish origin.

There are old smelter ovens concealed by bushes near the base of this small spur. The smelters and related infrastructure are difficult to see until you are virtually standing on top of them. They were used to concentrate antimony and other metals. The location is close to the mouth of a gully that provided the easiest natural path down from Antimony Peak (6,848 feet). The GPS coordinates for this location are 34 degrees 52' 48", –119 degrees 8' 6"

These smelters were built by Boushey & Co. which was a company headed by Stephen Boushey and his partners, E. J. Weston (an architect), and Francis Pliny Fisk (F. P. F.) Temple (a banker). His partners were business men (investors) rather than miners as such. They had staked mining claims in this area in 1872/73 and had built smelters at the foot of the mountain by 1878. Before 1878, it seems like they were shipping unprocessed ore. In April 1876, the Los Angeles Herald reported that this operation was producing three and a half tons of crude antimony per day which was sold in San Francisco.

An old document claimed Boushey & Co. had taken over an earlier Spanish mine. That sparked my interest but I did not find any evidence to support this. Everything I saw at the smelter site fits with a post 1870s operation rather than something half a century earlier.

Formal mining claims on Antimony Peak were filed in 1872 and 1873. At the time, the fee to file each of these claims was $35. The animony was mostly in the form of stibnite (antimony sulfide) along with antimony oxides. The ore contained trace amounts of silver and other metals.

The oven or furnace at the site appears to be built with local rock.....

"The mountain west of this ledge is capped with metamorphic sandstone, which Mr. Boushey has tested for lining the furnaces of his smelting works, and pronounces it equal to the best

imported firebricks. He showed me some of this stone that has been subject to frequent intense heat in his furnaces, and it was apparently uninjured."

California Journal of Mines and Geology, Volume 8, 1 October 1888.

On closer inspection, I'm reasonably sure these are post 1870s smelters, and are indeed those built by Boushey & Co.

The initials "TCARR" are moulded into the firebricks at the Boushey site. They were imported from Thomas Carr & Son, Bells Close, Scotswood,

Newcastle-upon-Tyne in England. In the early 1890s, the business was owned by Walter Scott & Co., who continued to use the 'Carr' name. The company active between c.1827 and 1918. Discarded slag which was separated as a byproduct of the smelting process. These rolled-up balls of scrap metal are strewn about the area near the smelters. I assume the metal was used in the smelting process (perhaps as a catalyst?). Antimony expands on solidifying, a rare characteristic that it shares with water. It is used in making metal alloys such as pewter and also for machine bearings.

Only a small amount of antimony is needed to add hardness and expansion properties to the alloy.

Antimony was used to make an alloy called babbet formerly used in making low-speed bearings and casings in early piston engines.

Antimony has many other uses. It was an ingredient in setable type face used in early printing presses.

More recently, antimony is used in the electronics industry to make some semiconductor devices, such as infrared detectors and diodes.

Antimony compounds are used to make flame-proofing materials, lead-based pigments, and ceramic enamels. It is used in bullets (ammunition), lead shot, and solder.

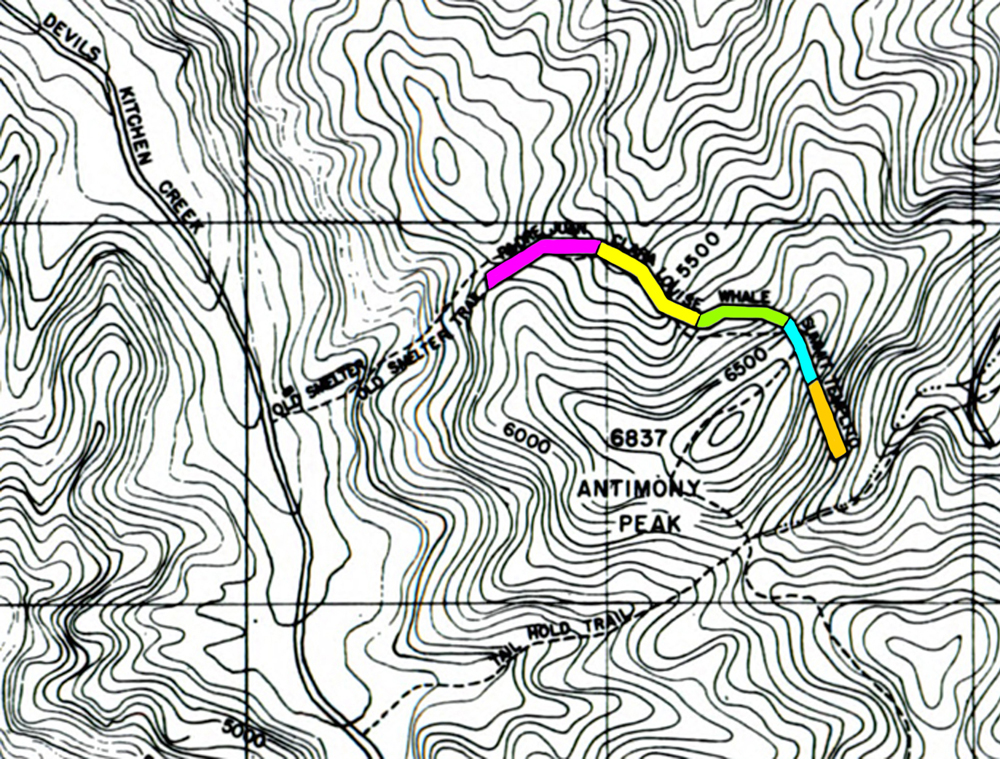

A lead-antimony alloy is used in lead‑acid batteries (car batteries). A map showing where the 1870s mining claims were located..... Each claim was 200 feet wide and was about 33 acres in size. The mining claim for Lot 37 (orange) was named the "Templito Quartz Mine".

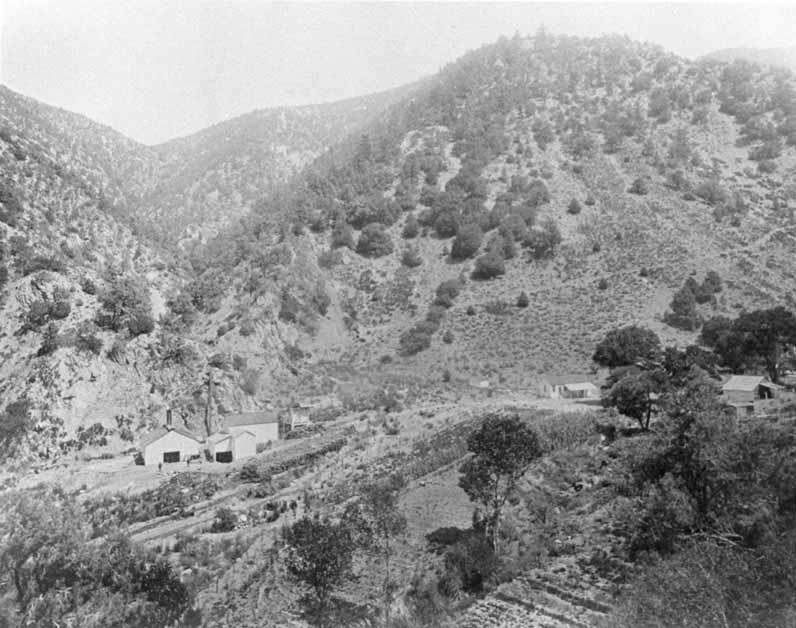

F. P. F. Temple was known among his Spanish-speaking friends as "Templito"(i.e. little Temple) because of his five-feet-four stature. A photo of the Boushey mining complex in San Emigdio Canyon. I estimate this photo was taken between 1880 and 1890.

The following describes the process of concentrating the ore at the Boushey works circa 1880....."The rock in which the antimony is found, Mr. Boushey says,

is not very hard, and is easily blasted out. It is put into crucibles and covered up. Heat in then applied. The ore runs through holes in the bottom of the crucible in red hot streams.

In the night these streams show all the colors of the rainbow. They consist not of pure antimony, but of the natural ore, what is left in the crucible being only the earthy matter.

This ore would burn up if the vessel in which it runs were not covered up to keep the air away. Mr. Boushey once tried a reverberatory furnace, but the descending flames and air caused the

ore to burn so rapidly in the fierce heat that it not only disappeared, but carried off all the earthy matter with it. Antimony melts at 842 degrees Fahrenheit, and excessive heat is not

required. Wood fuel is sufficient. The melting point of lead is 619 degrees Fahrenheit. Up to the present time the ore thus obtained has been shipped to France to be refined."

"As it runs from the crucible it consists of sulphuret of antimony. It must first be carefully heated so that the oxygen of the air will unite with it without

it burning. The outcome of this operation is then mixed with carbonate of soda and powered charcoal and again heated. These substances burn away the sulphur and leave the antimony, but not

quite in a pure state. It is again melted with a little of its own oxide, or rust. This last process yields the metal in its purity. The erection of a refinery at the mouth of the mine will

save a very large percentage in carriage and in railroad and ocean freight. All the antimony used in the United States has been shipped to France or England as ore, and shipped back in its

metallic form."

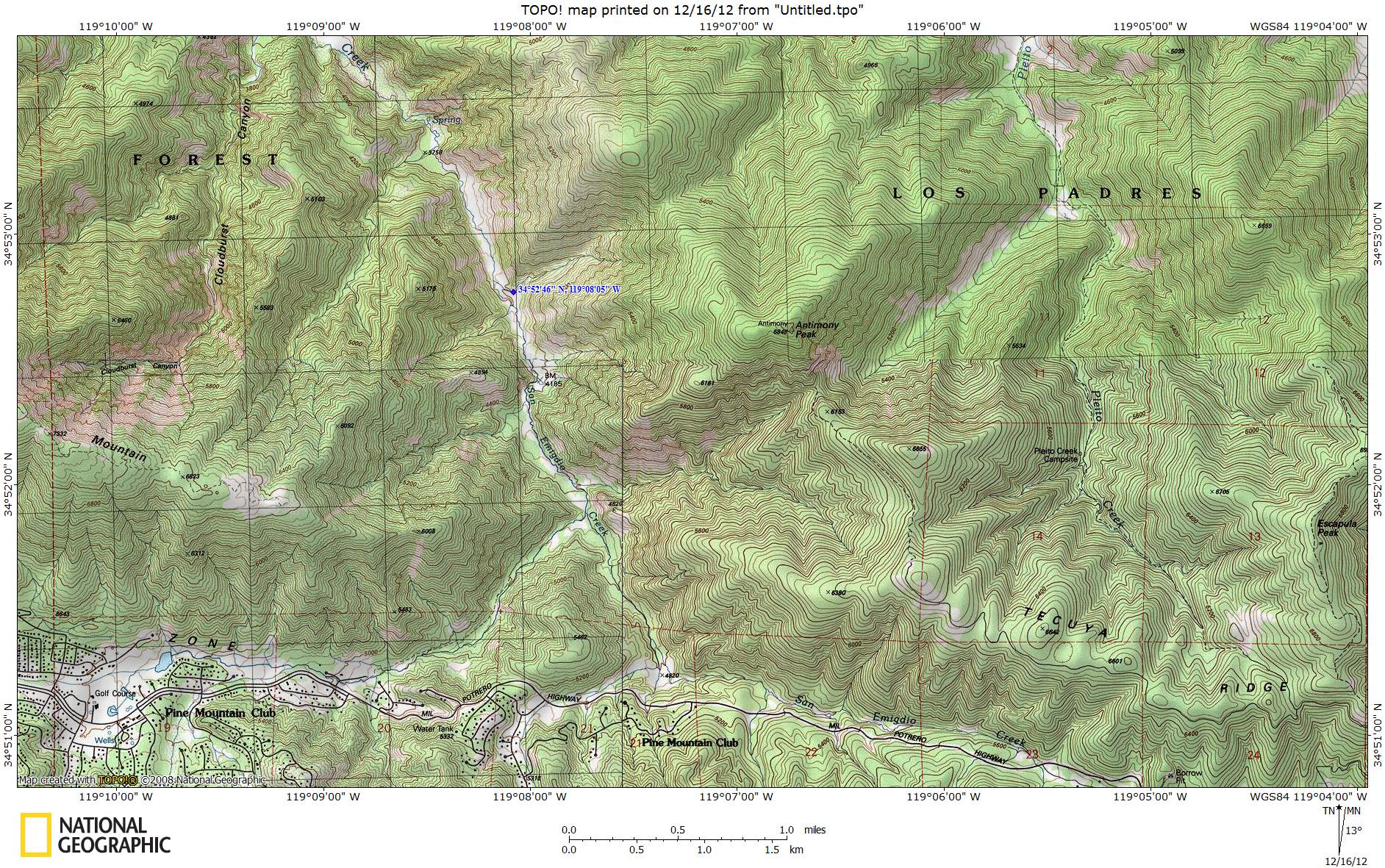

The GPS coordinates are 34 degrees 52' 48", –119 degrees 8' 6" as shown on the map. Allow about an hour and a half each way for this hike starting from the edge of Pine Mountain Club

(from the end of Nesthorn Way). A HISTORICAL OVERVIEW:

Peter Gray

KEY:

fuchsia: Padre Juan Quartz Mine

yellow: Clara Louisa Quartz Mine (survey#118 lot#38 filed 1st October 1872)

green: Whale Quartz Mine (survey#128 lot#40 filed 1st October 1872)

blue: Summit Quartz Mine (survey#115 lot#39 filed 30th January 1873)

orange: Templito Quartz Mine (survey#116 lot#37 filed 1st October 1872)

The following is a description of the property in October 1891 after Stephen Boushey had died and the property was put up for sale......

"Many thousands of dollars have been expended in the development of these mines, and they are now so far developed as to require but a very small amount of dead work to put them on

a paying basis. A never failing supply of water, at least 300 miners' inches in the dryest season, flows down the canyon near the mine. The plant consists of a 20-horse power engine

and boiler complete, rock breaker, 3 concentrators, which are capable of handling at least 25 tons of ore every 24 hours. There is also a dwelling-house, barn and the usual buildings

and outhouses connected to such places, built on a homestead of one hundred and sixty acres, with garden, alfalfa meadows, orchard and vineyard."

The San Francisco Examiner, 16 October 1891, page 10.

The main dwelling (that was occupied by Alexander Boushey at the time) was completely destroyed by fire in July 1883 (and presumably re-built).

The Kern County Land Company purchased the property in 1892.

(A reverberatory furnace is a furnace in which the roof and walls are heated by flames and radiate heat on to material in the center of the furnace. It works something like a kiln.)

The passages quoted above are from a newspaper article published in The Sun (New York), 29 August 1880 on page 6

![]()

It appears the San Emigdio antimony deposits were first worked by Indians as the source of pigment for making paintings which can still be seen on

sandstone in the vicinity of Antimony Peak (Jermain and Ricker, 1949).

The San Buenaventura Mission operated an antimony mine in this area in the late 1810s and/or 1820s (documented).

During the American era, the deposits were rediscovered in September 1853 by William Phipps Blake who served as a geologist with the Pacific Railroad Survey

of the Far West. He reported finding the remains of an abandoned "forge or furnace" at a place his Indian guide (Jose) called "Campo de los Americanos".

It appears that E. J. Weston was the person who found the antimony deposit that started the development of this mining operation: "In 1870, E. J. Weston and others had put

up a saw mill in the vicinity, and while Mr. Weston was prospecting on this mountain, he discovered the sulphuret of antimony."

Formal mining claims were filed on Antimony Peak in 1872 and 1873. Records indicate that the first "modern" smelters were built

in San Emigdio Canyon in 1878 about a mile and a half below the deposit that was near the summit of Antimony Peak.

Sixty tons of metallic antimony was produced in 1882. Later, a new company named the Anglo-American Association is reported to have shipped several

railway carloads of metallic antimony to New York during 1885 (Jermain and Ricker, 1949).

The Boushey company and Anglo-American Association, hauled their ore to the canyon floor with mules along a path that switched back and forth down the

steep west side of Antimony Mountain. Metallic antimony from the smelter was then hauled in wagons to Bakersfield

and from there by railroad.

Intermittent mining continued until 1892 when the Kern County Land Company purchased the claims.

Since that time active mining has only occurred at two brief intervals during the First and Second World Wars.

In 1914, the price of antimony tripled to over 20 cents per pound, and mining and smelting operations were briefly resumed,

apparently using the old Boushey smelters. This operation shipped five or six railway carloads of ore during World War I.

In 1940 major exploratory drilling and trenching work was performed by the U.S. Bureau of Mines pursuant to a Congressional mandate to determine whether the area was suitable

as an emergency antimony reserve. For seven months, from November 1940 through May 1941, a crew headed by two mining engineers camped in a meadow just north of the peak.

During that period they built over 2.5 miles of roads and trails and dug 80 trenches.

In 1941, Charles Fife from Frazier Park mined and shipped about 5 tons of ore which contained 35 percent antimony.

In 1957-58, the Big Pine Mining Company mined about 3 tons of ore.

It is estimated that no more than 600 tons of metallic antimony has been produced from the antimony mines since 1882.

The remains of the 1957 workings consist of a caved-in tunnel and a wooden structure that can be found by following a fading road about half a mile down the north

side of the mountain. The demolished remnants of a cabin from the 1957 operations can be found in the flat area a few hundred yards north and east of the summit.

In June 1970, the Tenneco Mining Corp. commissioned a four-man survey crew from Glendale to file mining claims and dig a trench.

A geologist and other Tenneco employees occasionally came to assist the survey crew.

The road that was carved out on the south side of the peak by the Big Pine Company in 1957, now overgrown and blocked in places by

small slides, provides the most convenient way to climb Antimony Peak today.

![]()

telephone: +1 (661) 242-1234

![]()

![]()

![]()

![]()